Introduction

In the realm of recreational activities, Gel Blaster Guns have emerged as more than just a source of entertainment; they serve as catalysts for social interaction and teamwork. This blog delves into the pivotal role that Gel Blaster Guns play in fostering meaningful social connections and enhancing team dynamics.

The Power of Shared Experiences

Gel Blaster Gun battles create shared experiences that bond participants together. Whether it's strategizing, coordinating attacks, or celebrating victories, these shared moments forge strong interpersonal connections among players.

Communication and Collaboration

Effective communication is key to success in Gel Blaster Gun battles. Players must work together, exchanging information, coordinating movements, and adapting strategies on the fly. Through collaborative efforts, individuals develop teamwork skills and learn the value of cooperation.

Building Trust and Camaraderie

In the heat of battle, trust is paramount. Gel Blaster Gun games Gel Blaster Guns provide opportunities for individuals to demonstrate reliability, leadership, and support for their teammates. As trust grows, so does camaraderie, leading to deeper bonds both on and off the Gel Blaster Guns battlefield.

Inclusive and Welcoming Environment

Gel Blaster Gun communities are known Gel Blaster for their inclusivity and welcoming nature. Players of all backgrounds, ages, and skill levels come together to enjoy the game, fostering a diverse and vibrant community where everyone feels valued and accepted.

Opportunities for Socialization

Gel Blaster Gun events, tournaments, and meetups serve as platforms for socialization and networking. These gatherings bring enthusiasts together, providing opportunities to share tips, exchange experiences, and form lasting friendships with like-minded individuals.

Real-world Applications

The teamwork, communication, and leadership skills cultivated through Gel Blaster Gun gameplay extend beyond the battlefield. Participants often find that the lessons learned in the game translate into improved collaboration and cooperation in professional and personal settings.

Conclusion

Gel Blaster Guns serve as more than just recreational tools; they are vehicles for social interaction, team building, and personal growth. By fostering communication, collaboration, and camaraderie, Gel Blaster Gun gameplay enriches lives and strengthens communities, one battle at a time.

What are control panel systems and why are they critical pieces of plant infrastructure?

Control panel systems, often referred to simply as control panels, are integral components of various industrial and commercial systems. They provide a centralized interface for monitoring, controlling, and managing equipment, processes, and operations across diverse industries such as manufacturing, energy and utilities.

Control panels enable increased efficiency and precision in processes, reducing the need for manual labor and human intervention. They also play a crucial role in ensuring the safety and reliability of industrial equipment and allowing for remote monitoring and control.

Here’s a quick run-down on how control panel systems work:

Control panel functionality

Control panels possess a wide range of functionality, depending on the specific application and industry. They may offer capabilities such as:

> Monitoring and displaying real-time data from sensors, meters, and instruments.

> Control of the operation of machinery, equipment, and processes through switches, buttons, and graphical interfaces.

> Implementation of logic and automation using programmable logic controllers (PLCs), relays, and other control devices.

> Provision of alarms, notifications, and alerts for abnormal conditions or events.

> Configuration and adjustment of system parameters and setpoints.

Integration with other systems and devices through communication protocols such as Modbus, Profibus, Ethernet/IP, and DeviceNet.

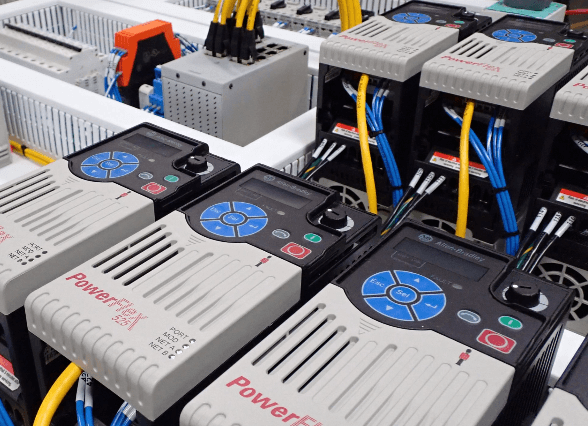

Control panel components

Control panels typically consist of several key components, including:

> A Human-Machine Interface (HMI) displays operational data and allows operators to interact with the system through touchscreens, buttons, and indicators.

> Controllers such as PLCs, microcontrollers, or distributed control systems (DCS) execute control algorithms and logic.

> Power distribution components distribute electrical power to equipment and devices, including circuit breakers, fuses, contactors, and terminal blocks.

> Input/Output (I/O) modules connect sensors, actuators, and other field devices to the control system.

> Communication Interfaces in the form of ports and modules connect the control panel to external devices, networks, and systems.

> Protective enclosures or cabinets house the control panel components, providing physical protection from environmental hazards such as dust, moisture, and temperature extremes.

> Electrical wiring, cables, and connectors interconnect components and devices within the control panel.

Control panel design considerations

Designing control panel systems requires careful consideration of various factors to ensure functionality, reliability, and safety. Key design considerations include:

> Electrical Design: Ensuring compliance with electrical codes and standards, proper sizing of components, and adherence to safety guidelines.

> Environmental Conditions: Selecting appropriate enclosure materials and protection ratings to withstand environmental factors such as temperature, humidity, dust, and corrosive substances.

> Ergonomics: Designing user-friendly interfaces and control layouts for intuitive operation and efficient human-machine interaction.

> Scalability and Expandability: Designing modular and smart manufacturing flexible control panel systems that can accommodate future expansions, upgrades, and modifications.

> Maintenance and Serviceability: Incorporating features such as access panels, diagnostic tools, and clear labeling to facilitate maintenance, troubleshooting, and repair.

Control panel applications

Control panel systems find applications across a wide range of industries and sectors, including:

> Industrial Automation Solution: Controlling and monitoring manufacturing processes, machinery, and production lines in industries such as automotive, aerospace, Automation Solution food and beverage, and pharmaceuticals.

> Building Automation: Managing HVAC (Heating, Ventilation, and Air Conditioning), lighting, security, and access control system design in commercial buildings, hospitals, schools, and hotels.

> Energy Management: Monitoring and controlling power generation, distribution, and consumption in utilities, renewable energy systems, and smart grids.

>Transportation: Managing signaling, traffic control, and railway systems in transportation infrastructure such as airports, railways, and highways.

Control panel systems: essential for smart manufacturing and digital transformation

At the core of the manufacturing facility control panel systems play a critical role in optimizing operational efficiency, enhancing safety and ensuring compliance is met across diverse industrial and commercial applications.

Modern and connected control panels combined with effective design, integration, and maintenance of control panel systems are essential for achieving your desired smart smart manufacturing manufacturing and digital transformation goals of predictive maintenance and real time, contextualized data on a mobile device.

Struggling with old technology? Don’t know where to start?

AutomateIT’s smart manufacturing consultants are able to meet you where you are at along your journey toward smart factory. Let’s get started!

417.429.4320

[email protected]

A Comprehensive Guide to Forklift Attachments

How to choose the right attachments to maximize the efficiency and versatility of your forklift.

Introduction to Forklift Attachments

Forklift attachments have always been a highly cost-effective way for a forklift to perform a wider variety of tasks above and beyond lifting and shifting pallets.

The greater versatility offered by forklift attachments lets businesses do more with less equipment, improving overall both worker and equipment productivity while conserving business cash and capital.

The types of forklift attachments and what they do

The days of using a forklift just for lifting are long gone. There’s a forklift attachment for almost any task from self-dump hoppers and buckets, wire mesh handlers, heavy-duty spreader bars, work platforms, lift hooks, truss booms, jib booms, load n tows, lift n tows, replacement forks, parts and bars, and more.

What are your forklift attachment choices and what do they do? We’ve broken the most popular forklift attachments by category.

Forklift Hoppers and Buckets

Heavy Duty Self-Dump Hopper

A forklift self-dump hopper is the perfect way to collect, move and dispose of waste around the job site with a forklift such as concrete, plaster, brick and other construction waste.

The key feature of a self-dump hopper (as the name suggests) is the ability to trip the hopper to lift the load upwards and forwards to make it easy to empty the hopper and dispose the waste. Hoppers typically range in load capacity from ½ CUYD up to 5 cuyd.

Heavy Duty Self-Dump Bucket

Attaching a forklift bucket to an extendable-reach forklift can suddenly make it incredibly easy to place materials in hard-to-reach places like elevated positions and behind high walls.

You can choose from a manual bucket where the bucket can be tripped by the operator via a manual handle or a hydraulic bucket solution that provides precise control of the discharge.

Heavy Duty Forklift Bucket

A forklift bucket is an easy way to give your forklift all the capabilities of a loader without the extra cost. Most forklift buckets are available in both Quick-Tach and Slip-on-the-fork styles.

The Quick-Tach style allows connection directly to the end of the boom for a safe and strong connection. The removal of the forks and carriage system saves 700 to 1,000 lbs, enabling the forklift to lift heavier loads.

Forklift Booms, Bars and Handlers

Forklift Jib Boom

A forklift Jib Boom is an extendable telescopic boom that you can attach to a forklift to place heavy loads over or under obstacles. Most forklift job booms are suitable for both straight-mast and extendable-reach type forks.

Quick-Tach Truss Boom

A Quick-Tach Truss Boom enables you to combine the lifting capability of a crane with the speed and maneuverability of an extendable reach forklift.

With a vertical reach of up to 15’ and load capacity from 2,000 lbs to 22,000 lbs, the Star QT Truss Boom is ideal for metal building erection, setting wooden trusses, putting up post frame buildings and many more crane type jobs.

Heavy Duty Spreader Bar

A spreader bar allows you to manage long lengths of material like beams and roofing sheets easily with your forklift. It’s perfect for handling rebar, rebar cages, building beams, and steel and wood trusses making it a popular forklift attachment with building erectors.

Wire Mesh Handler

A forklift wire mesh handler takes the hard work and hassle out of loading and moving wire mesh panels around the yard or job site. A good one will easily handle up to 7,000 lbs capacity,

Platforms

Safety Work Platform

One key advantage of an extendable reach forklift safety platform is that it can safely take you places where scissor lifts can’t. This makes it perfect for hard-to-reach places such as reaching over obstructions. It is also faster and cheaper than erecting scaffolds.

A good forklift safety platform should have an expanded metal deck for a wider work area and a full perimeter guard rail for superior safety.

Safety Loading Platform

A forklift safety loading platform helps you to load and unload heavy, awkward equipment that won’t fit over your forks safely and easily. The platform makes it easy to move things round, cutting labor costs, preventing back injuries and reducing damage to equipment.

Things to consider before buying a forklift attachment.

Is the forklift attachment engineered to standard?

Manufacturers of forklift attachments must ensure they meet the applicable guidelines as defined in American National Standards Institute B56.1-1969 and that operator use is without risk to health and safety as is reasonably practical when used in accordance with the supplied guidelines.

This duty includes conducting analysis, testing or an examination and providing specific information about the attachment.

If you ignore the uses, load and capacity ratings of your equipment and attachments, or circumvent ANSI and OSHA safety standards by using home-made, non-certified machinery attachments, you’re endangering your equipment, contracts, workers and your entire job site.

Is the forklift attachment plated and includes operator safety instructions?

The forklift attachment needs to be plated to manufacturer specifications including capacity and safe operation. Operator safety instructions need to be visible and easily accessible via the manual holder.

Is the attachment built for safety and to last?

Ensure the forklift attachment has safety and longevity in mind. The attachment should come standard with safety features such as retaining pins behind the heel of each fork that can be secured with hairpins or cotter pins; safety chains that can be wrapped around the fork carriage; pull spring-loaded pins and internal stops to ensure the extendable items such as telescopic boom sections cannot Star Industries be accidently pulled all the way out.

Check with the dealer or manufacturer that all items supplied with swivel hooks, bolted shackles, chains, pin plates etc are properly rated for use with forklift attachment.

How the attachment is manufactured is another important consideration. For example, if it’s a bucket, ask the attachment seller if it’s manufactured with a heavy-duty steel shell with continuous welded seams inside or out that add greater strength and attachment life.

Does it fit your brand of forklift and specifications?

Make sure the attachment has been tested and rated for your forklift brand, model and attachment method. The attachment should not exceed the capabilities of your machine as it may lead to operator injury or damage to the forklift.

What warranty and support are on offer?

Check with the seller the manufacturer warranty and support. If it’s not five-years, why not? What support does the dealer or manufacturer offer post sale? Are they located in the USA? Can you speak to a real person if you have a question or a problem? Do they carry spare parts for your attachment?

Get more out of your forklift with Star Industries’ selection of heavy-duty forklift attachments and accessories for the warehousing, construction and fleet rental industries.

Star Industries attachments — and attachment storage solutions — are precision-engineered and manufactured for the rigors of the warehousing and construction industries.

This makes them a popular choice for owners and operators of fleets of forklifts who are seeking to maximize the ROI on their valuable construction, building and earthmoving equipment.

Star Industries forklift attachments are super tough, USA made and available in both ITA and Shaft Mounted attachment options. Star Industries even offers an industry-leading five-year guarantee on most of its forklift attachments.

Visit Star Industries to learn more.

Empowering Innovation: The Role of Low-Code Development Platforms in Digital Transformation

In the fast-paced digital landscape, innovation is not just a buzzword – it's a strategic imperative for businesses looking to stay relevant and competitive. At the heart of this innovation lies low-code development platforms, the catalysts driving transformative change across industries. Let's explore how these platforms are empowering innovation and driving digital transformation.

The Digital Imperative

In an era defined by rapid technological advancements and evolving customer expectations, digital transformation has emerged as a critical priority for organizations worldwide. At its core, digital transformation is about leveraging technology to drive innovation, enhance operational efficiency, and deliver superior customer experiences. Low-code development platforms play a pivotal role in this journey by providing organizations with the tools and capabilities needed to accelerate their digital initiatives.

Accelerating Time-to-Value

One of the key advantages of low-code development platforms is their ability to accelerate time-to-value – the time it takes for organizations to realize tangible benefits from their digital investments. By streamlining the application development process and empowering developers to build and deploy applications rapidly, these platforms enable organizations to bring new ideas to market faster, seize opportunities, and stay ahead of the competition.

Enabling Agility and Adaptability

In today's fast-paced business environment, agility and adaptability are essential for success. Low-code development platforms empower organizations to respond swiftly to changing market dynamics, customer preferences, and emerging trends. By providing a flexible and scalable development environment, these platforms enable organizations to iterate on ideas, experiment with new features, and pivot quickly in response to evolving business requirements.

Fostering Collaboration and Innovation

Innovation thrives in environments where collaboration is encouraged, and ideas can flow freely. Low-code development platforms foster collaboration by providing a unified platform where developers, business Low-code Platform users, and stakeholders can collaborate seamlessly throughout the application development lifecycle. By breaking down silos and fostering cross-functional teamwork, these platforms enable organizations to harness the collective creativity and expertise of their teams to drive innovation and achieve their digital transformation goals.

Unlocking New Opportunities

Low-code development platforms unlock new opportunities for innovation by democratizing app development and empowering individuals with varying levels of technical expertise to contribute to the development process. By providing user-friendly tools, templates, and visual interfaces, these platforms enable citizen developers – individuals with limited coding experience – to participate in the creation of custom applications, prototypes, and proof-of-concepts, fostering a culture of innovation and experimentation.

Conclusion

In conclusion, low-code development platforms are at the forefront of driving digital transformation and empowering organizations to innovate and thrive in today's digital landscape. By accelerating time-to-value, enabling agility and adaptability, fostering collaboration and innovation, and unlocking new opportunities, these platforms provide organizations with the tools and capabilities needed to succeed in an increasingly competitive and dynamic business environment. As organizations continue to embrace low-code development platforms, the possibilities for innovation and transformation are endless.

透過 3A 提升您的行動體驗:遊戲的下一個變革

在當今快節奏的世界中,手機遊戲已不僅僅是一種消遣;它還成為一種娛樂方式。這是一種生活方式。隨著科技的不斷發展,消費者不斷尋找下一個重大事物來增強他們的遊戲體驗。 3A 即將問世,這項全新的行動服務將徹底改變您隨時隨地的遊戲方式。

平凡的遊戲體驗的日子已經一去不復返了。有了 3A,準備好沉浸在前所未有的興奮和便利的世界中。這個創新平台擁有新穎的設計,不僅增強了樂趣,而且使遊戲比以往任何時候都更容易上手。

想像一下,只需在智慧型手機上輕按幾下,即可從日常通勤無縫過渡到令人興奮的遊戲會話。有了3A,這一切就變成了現實。無論您是在等待早晨的咖啡,還是在會議之間休息一下,提升遊戲體驗的能力都在您的掌控之中。

但 3A 與其他行動遊戲服務有何不同?這一切都在於對細節的關注和對提供真正卓越的用戶體驗的承諾。從直覺的控製到令人驚嘆的圖形,3A 的每個方面都經過精心設計,以確保所有年齡段的玩家都能獲得最大的樂趣。

此外,3A 為您喜愛的遊戲注入了新的活力,提供新鮮的挑戰和體驗,讓您流連忘返。透過專為您的遊戲偏好而設計的平台,告別單調,迎接無限可能。

總而言之,如果您準備將行動遊戲體驗提升到新的水平,3A 就是您的最佳選擇。憑藉其無與倫比的便利性、創新設計和對卓越的承諾,3A 將重新定義您的遊戲方式。那為什麼還要等呢?今天就加入這場革命,讓 3a 3A 讓您的生活更加精彩。